Medical Gas Pipeline System

Medical Gas Pipeline System

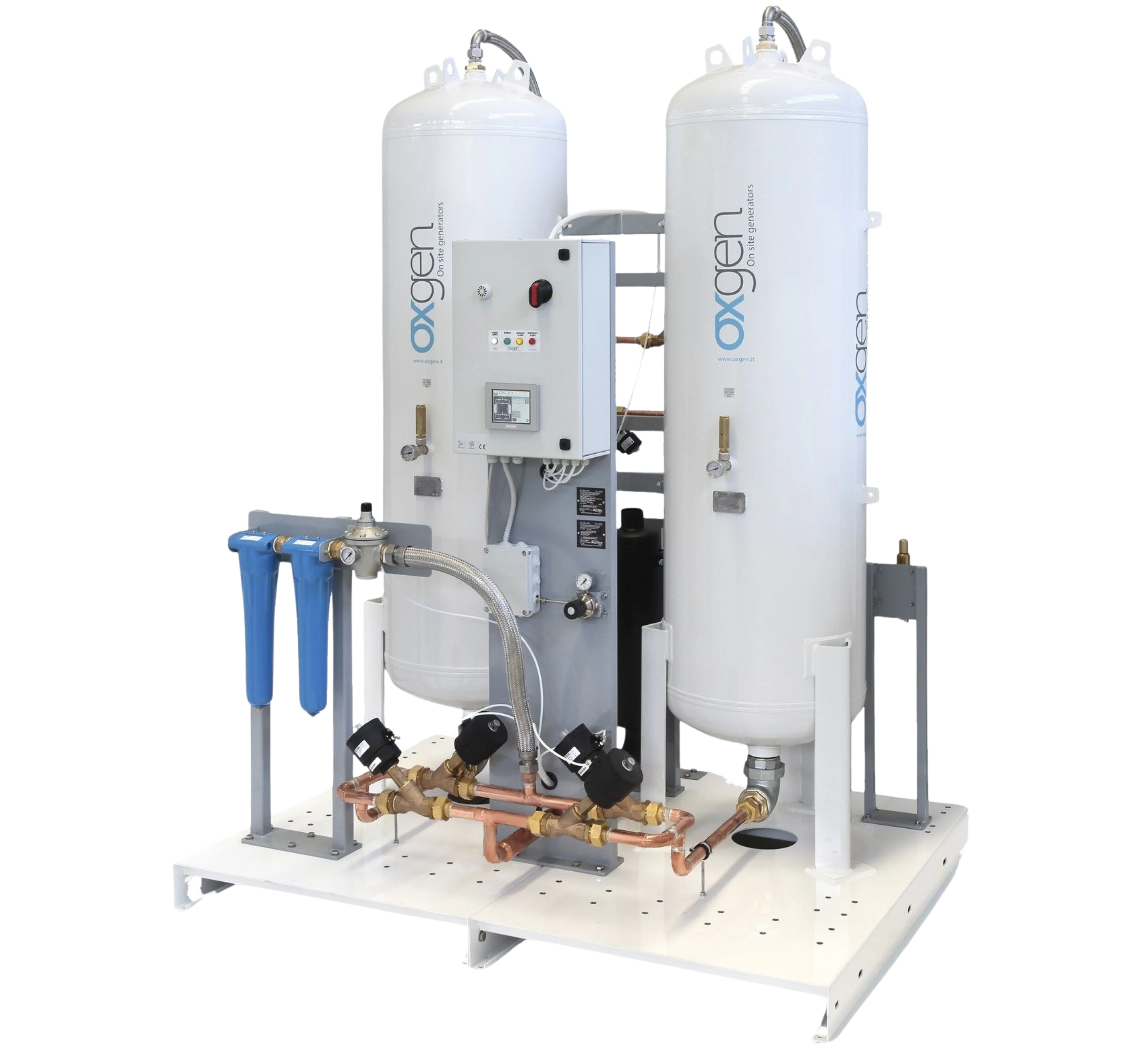

Sanmedi offers advanced medical gas pipeline systems along with a comprehensive range of accessories for the safe and efficient distribution of oxygen and other essential medical gases in hospitals and healthcare facilities. With a focus on reliability and performance, we deliver complete, no-frills solutions using proven, cost-effective technology.

Sanmedi has successfully executed installations in leading hospitals and medical institutions across the region. Our commitment to quality craftsmanship—from durable piping to precision-engineered accessories—ensures long-term system integrity.

At Sanmedi, we don’t just install; we partner. Our dedicated after-sales support and maintenance services ensure uninterrupted performance and peace of mind for our clients.

What Makes a Reliable Medical Gas Pipeline System?

At Sanmedi, we ensure every system is built to meet the highest safety and performance standards:

Non-interchangeable design to prevent cross-connection

Reliable gas & vacuum supply at correct pressure, flow, and purity

High-quality, approved materials

Clean, contamination-free components

Monitoring & alarm systems for early alerts

Proper pipeline marking & labeling

Thorough testing and commissioning

Spot checks to monitor gas quality

Safe, efficient operational management

Built-in safety features to maintain gas standards

Importance of Design & Standards in MGPS

The design and installation of a Medical Gas Pipeline System (MGPS) directly affect its performance and safety. Therefore, it is crucial that these processes meet the highest quality standards.

Responsibility for a complete system includes design, installation, operational guidance, and verification, which may be managed by a single agency or multiple specialized teams.

Globally, most countries follow ISO 7396 for MGPS and anaesthesia scavenging systems. Other widely accepted standards include HTM 2022 and NFPA 99.

For instance, NFPA 99 (Sec. 4-3.1.9.1) requires that medical air compressors must not introduce oil, water, or contaminants into the pipeline. Using non-medical-grade compressors can lead to serious risks, including the mixing of toxic substances into the medical air supply.

Water is the most common and damaging contaminant in medical air lines. It can bypass filters and enter anaesthesia machines, ventilators, and even reach the patient. Moisture promotes bacterial growth, corrodes copper pipelines, and in low temperatures, can freeze and block airflow. These issues not only compromise patient safety but also damage costly equipment. Importantly, not all air compressors are suitable for medical use—non-medical-grade units may introduce oil and hydrocarbons, which is why proper filtration and hydrocarbon monitoring are essential in any medical gas system.